Top Best Practices for Safe and Compliant Chemical Storage

- Kalium Solutions

- Jun 17

- 4 min read

Improper chemical storage is one of the most common—and preventable—safety hazards in industrial, laboratory, and manufacturing environments. From minor leaks to serious chemical reactions, poor storage practices can lead to workplace injuries, environmental contamination, or non-compliance with regulatory standards.

To avoid such risks, businesses must follow a set of clearly defined chemical storage requirements and implement effective chemical storage solutions. In addition, investing in employee education through chemical storage training and chemical spill training, as well as using the best SDS authoring software, are crucial steps toward creating a culture of safety.

This article outlines the top best practices to help your organization store chemicals safely and remain compliant with local and international safety regulations.

1. Know What You're Storing

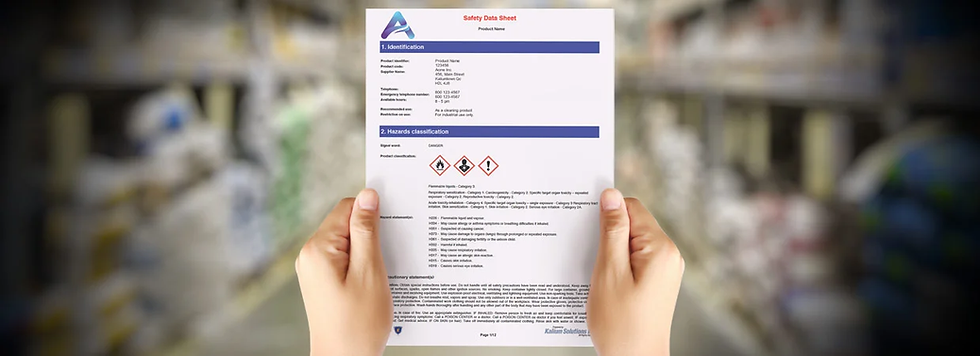

The first step in chemical storage is to know exactly what substances are on-site. Maintain an accurate and up-to-date inventory of all chemicals, including their Safety Data Sheets (SDS). This ensures you're aware of each chemical's hazards, storage needs, and interaction risks.

Utilizing the best SDS authoring software can streamline this process by helping organizations create and manage SDSs that comply with regulatory frameworks such as WHMIS, GHS, or OSHA standards. A clear and organized inventory not only helps with compliance but also supports safe chemical handling.

2. Label Everything Clearly

Each chemical container must be labeled accurately and legibly. Labels should include the chemical name, concentration, hazard classification, and key safety information. Proper labeling helps prevent mix-ups, especially during handling, transfer, or spill response situations.

In line with chemical storage training, employees should be taught how to recognize and interpret labeling systems like WHMIS or NFPA, ensuring clarity across departments.

3. Separate Incompatible Chemicals

Certain chemicals, when stored together, can react violently or emit toxic gases. For example, storing oxidizers near flammables or acids near bases can be extremely dangerous.

Implement storage strategies that segregate incompatible substances. Use color-coded shelving or labeled containment bins to keep reactive substances apart. These practices are part of the core curriculum in chemical storage training and reduce the risk of accidental chemical reactions.

4. Use Approved Storage Containers

Never store chemicals in makeshift or unlabeled containers. Always use containers that are approved for chemical storage and are compatible with the substance they hold. Ensure they are sealed tightly and resistant to corrosion, heat, or light where applicable.

Proper container usage is also an important point covered in chemical spill training, where mishandling of damaged containers can escalate into emergencies.

5. Ensure Ventilation and Temperature Control

Chemicals should be stored in areas with adequate ventilation to prevent the buildup of harmful fumes. In addition, many substances have specific temperature storage requirements. Heat can cause volatility in flammable chemicals, while cold temperatures may compromise container integrity.

Temperature monitoring systems and ventilated chemical cabinets are practical chemical storage solutions that support safety and compliance with regulatory guidelines.

6. Provide Secondary Containment

Secondary containment systems such as trays, spill pallets, or bunded shelves are critical for managing leaks or spills. These systems prevent chemicals from spreading and provide a first line of defense against environmental damage.

Integrating secondary containment is not only a smart investment but often a legal requirement under many chemical storage requirements.

7. Train Employees Regularly

All personnel handling or working near hazardous materials must undergo chemical storage training. Training should include hazard communication, safe handling practices, emergency response, and proper use of storage systems.

In addition, chemical spill training is crucial for teaching workers how to respond effectively in the event of a spill—minimizing harm to themselves, others, and the environment.

Kalium Solutions offers tailored training programs to ensure your workforce stays informed and confident in their roles.

8. Maintain Safety Data Sheets (SDS)

SDSs provide vital information about the properties, hazards, and handling instructions of chemicals. They must be readily accessible to all employees.

Companies should use the best SDS authoring software to generate accurate, compliant documents that are easy to maintain and update. A robust SDS management system ensures you’re always audit-ready and your team has quick access to the data they need in emergencies.

9. Inspect and Audit Storage Areas

Chemical storage areas must be routinely inspected for compliance, cleanliness, and potential hazards. Regular audits help identify deteriorating containers, expired chemicals, or improperly stored substances before they become a problem.

Create a documented inspection checklist that aligns with your local canada chemical regulations, and involve cross-functional teams for accountability.

10. Prepare for Emergencies

Despite best efforts, spills and accidents can still happen. Emergency equipment like eyewash stations, fire extinguishers, spill kits, and ventilation systems should be placed near chemical storage areas and clearly marked.

Conduct drills and include chemical spill training in your safety program so all employees know how to act quickly and effectively during an emergency.

Kalium Solutions provides support for emergency preparedness through training, spill containment planning, and consulting on workplace safety strategies.

Final Thoughts

Proper chemical storage is not just about chemical compliance—it’s about creating a safe, productive work environment for your team. With the right mix of best practices, training programs, and technology, your organization can meet chemical storage requirements with confidence.

From implementing durable chemical storage solutions to investing in chemical spill training and leveraging the best SDS authoring software, every step you take reinforces your safety culture.

Kalium Solutions is here to help businesses like yours stay ahead of risks, regulations, and responsibilities. Are you ready to take your chemical safety program to the next level?

Comments